AURUNA® 215 Gold Iron Indium Electrolyte

AURUNA® 215 is a colour gold alloy electrolyte for decorative applications, preferably for parts coming into contact with the skin such as jewellery and watches. The essential advantage of the coatings is their freedom from nickel and cobalt, excluding skin allergies caused by these metals.

The weakly acidic gold electrolyte is easy to operate and suitable for rack and barrel, it works very colour-constant. Across a wide operating range, the coating colour (1N – 2N) is independent of pH-value and current density. By adding indium, a uniform colour is achieved.

Electrolyte characteristics

Electrolyte type: Weakly acidic

Metal content: 2.5 g/L Au, 0.5 g/L Fe, 1.0 g/L In

pH value: 4.0 (3.8 – 4.5)

Operating temperature: 35 (30 – 35) °C

Current density range: 1.5 (0.5 – 2.0) A/dm²

Plating speed: approx. 0.14 μm/ min at 1.5 A/dm²

Anode material: Pt-Ti, MMO (type PLATINODE® 147)

Coating characteristics

Coating: Gold-iron-indium

Alloy composition: 98.5 weight % Au 1.4 weight % Fe 0.05 weight % In

Colour of deposit: approx. 1N – 2N

Brightness: Bright

Hardness: 220 HV

Max. coating thickness: 3 μm

Density of the coating: approx. 17.5 g/cm³

Advantages

- Weakly acidic colour gold electrolyte

- Pale to light yellow coatings

- Colour-constant across a wide operating range

- Uniform colour

- For decorative applications

- Non-allergenic since free of nickel and cobalt

- The coatings are RoHS compliant

- Suitable for rack and barrel

AURUNA® 220 Gold Nickel Indium Electrolyte

AURUNA® 220 is a weakly acidic electrolyte for the deposition of gold coatings showing a colour which is a pale yellow with a light greyish shade. This colour is often called “14 carat Hamilton”. The process is used for decorative applications. Up to 5 µm thickness, the deposits are bright with constant colour. The electro- lyte, which can be used both for rack and barrel plating, works unproblematically and is easy to control.

Electrolyte characteristics

Electrolyte type: Weakly acidic

Metal content: 4.0 g/L Au, 5.0 g/L Ni, 1.5 g/L In

pH value: 3.5 (3.4 – 3.7)

Operating temperature: 30 °C (± 2 °C)

Current density range: 0.6 A/dm² (0.4 – 1.0 A/dm²)

Plating speed: approx. 0.06 µm/min.

Anode material: Pt-Ti, MMO (type PLATINODE® 167)

Coating characteristics

Alloy composition: Gold-nickel-indium

Fineness: approx. 96.5 % gold

Caratage: approx. 23 carats

Colour: 14 carat Hamilton

Hardness: approx. 270 HV 0.025

Maximum coating thickness: 5 µm

Density of the coating: approx. 17 g/cm³

Advantages

- Gold electrolyte for decorative coatings

- Pale yellow colour (14 carat Hamilton)

- Au/Ni/In coatings

- Good corrosion and abrasion resistance

- For rack and barrel

AURUNA® 232 Gold Nickel Indium Electrolyte

AURUNA® 232 is a weakly acidic electrolyte for the deposition of gold coatings showing a colour which approximately corresponds to the standard colour 2 N according to ISO 8654. The process is used for decorative applications. Up to 5 µm thickness, the deposits are bright with constant colour. The electro- lyte, which can be used both for rack and barrel plating, works unproblematically and is easy to control.

Electrolyte characteristics

Coating characteristics

Fineness: approx. 97.5 % gold

Caratage: approx. 23.5 carats

Colour: approx. 2 N

Hardness: approx. 250 HV 0.025

Maximum coating thickness: 5 µm

Advantages

- Gold electrolyte for decorative coatings

- Light yellow colour, approx. 2 N

- Au/Ni/In coatings

- Good corrosion and abrasion resistance

- High deposition speed

- For rack and barrel

AURUNA® 311 Gold Cobalt Electrolyte

AURUNA® 311 is a strongly acidic alloy electrolyte for the adhesive direct gold-plating of stainless steel. It is preferably used for chromium-nickel steels, molybdenum steels and nickelbased alloys difficult to activate. Due to its strong activation effect, the electrolyte can be often successfully used as well for other passive materials difficult to plate.

The gold electrolyte is suitable for both strike gold layers and thick coatings in the decorative field. The coatings are ductile, low in pores and protect against corrosion. The alloy electrolyte can be used for rack and barrel operation as well as in reel-to-reel plating (e.g. spray and dip cells and brush).

AURUNA® 311 is also available as a cobalt-free special version.

Electrolyte characteristics

Coating characteristics

Advantages

- Hard gold electrolyte for the direct gold-plating of stainless steel

- Very good activation effect – without halogenides

- Low-pore, ductile and crack-free coatings

- Suitable for strike gold layers as well as for thick coatings

- Good throwing power

- Available as a cobalt-free special version

- The coatings are RoHS compliant

- Suitable for rack, barrel and reel-to-reel plating

AURUNA® 500 LC Rose Gold Electrolyte

AURUNA® 500 LC is a neutral electrolyte for depositing red 18 carat gold-copper coatings. The electrolyte works with low gold content, has a stable pH-value and works without free cyanide.

The alloy is mainly suitable for decorative applications such as jewelry and accessories. The layers are very hard and abrasion-resistant. As low-carat gold-saving coatings, they additionally exhibit a very good resistance to tarnishing and corrosion.

Electrolyte characteristics

Coating characteristics

Advantages

- Rose gold-copper layers

- Gold-saving coatings (approx. 18 kt)

- Tarnish and corrosion resistant

- Low gold content

- No free cyanide

AURUNA® 556 Fine Gold Electrolyte

The AURUNA® 556 gold electrolyte serves to deposit hard and bright fine gold coatings, making it ideal for decorative and technical applications. The electrolyte works in the neutral pH range with a high current efficiency of approx. 90 %.

Electrolyte characteristics

Electrolyte type:Neutral

Gold content: 8 g/l (7 – 9 g/l)

pH-value: 6 (5.8 – 6.2)

Temperature: 50 °C (45 – 55 °C)

Electrolyte density: Approx. 1.08 g/cm³ at room temperature

Current density: Up to 0.8 A/dm² (0.2 – 0.8 A/dm²) / 0.4 A/dm² for barrel plating

Deposition speed: Up to 0.5 µm/min (approx. 0.28 µm/min at 0.5 A/dm²) proportional to current density

Deposition rate: Approx. 108 mg/Amin

Current efficiency: Approx. 85 – 90 %

Coating Characteristics

Coating: Fine gold

Fineness: 99.9 %

Caratage: 24 carats

Colour: Yellow

Density: Approx. 19 g/cm³

Max. layer thickness: > 200 µm (10 µm bright)

Hardness: Approx. 250 HV 0.025

Classification: acc. to ASTM B 488-01 Type III, Code D (equivalent to Type III, Grade D acc. to MIL G 45204 C)

Advantages

- Gold electrolyte with high current efficiency

- Fine gold coatings with high hardness

- Suitable for decorative and technical applications

- Bright coatings up to 10 µm layer thickness

AURUNA® 5400 Hard Gold Electrolyte

AURUNA® 5400 the weakly acidic electrolyte deposits yellow, uniform bright hard gold coatings. The newly balanced brightener system of the electrolyte enables the operation in a very wide current density working range and allows a variable gold content at the same time. Due to the usage of special chemical components, the AURUNA® 5400 is equally suitable for rack and barrel application.

The deposited coatings are characterized by low porosity and an increased abrasion resistance, compared to coatings deposited in AURUNA® 539. Furthermore contacts coated with AURUNA® 5400 exhibit a low and long-time stable contact resistance and an excellent solderability. As well coatings up to 10 μm can be crack-free depositied in the electrolyte.

Electrolyte characteristics

Coating characteristics

Advantages

- Very wide operating current density range

- For technical and decorative applications

- High corrosion and abrasion resistance

- Low, stable contact resistance

- Classification according to ASTM B 488-01: Type I – II, grade C -D

AURUNA® 7000 Gold Iron Electrolyte

AURUNA® 7000 is used for depositing hard gold coatings in special high-speed equipment. The weakly acidic electrolyte has a wide operating range with easy bath maintenance and high plating speed. No oxidation of the alloy partner iron.

AURUNA® 7000 was specifically developed for the automatic high-speed gold-plating in equipment for selective plating and continuously working reel-to-reel lines. Due to vigorous electrolyte agitation (flow, spray), it allows the working at high current densities with stable long-time behaviour. It can be also operated as a gold strike electrolyte.

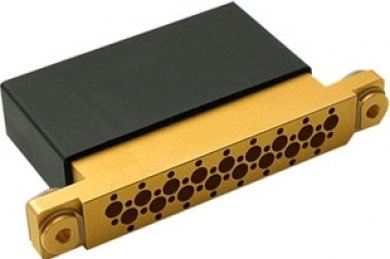

The deposits are solderable, low in pores, ultra-bright, hard and abrasion-resistant. They have a constantly low contact resistance. Therefore the electrolyte is excellently suitable for the gold-plating of electronic components such as connectors, contacts and edge connectors on printed circuit boards.

Electrolyte characteristics

Coating characteristics

Advantages

- For use in high-speed equipment

- No oxidation of the alloy partner iron

- High plating speed

- Low-pore, solderable, hard and abrasion-resistant coatings

- ASTM B-488-01, Type I-II, Code C-D

- The coatings are RoHS compliant

AURUNA® 8100 Gold Cobalt Electrolyte

AURUNA® 8100 is used for depositing hard gold coatings in special high-speed equipment. The weakly acidic high-speed electrolyte has a wide operating range with easy bath maintenance and extremely high plating speed.

AURUNA® 8100 was specifically developed for the automatic high-speed gold-plating in equipment for selective plating and continuously working reel-to-reel lines. Due to vigorous electrolyte agitation (flow, spray), it allows the working at high current densities with stable long-time behaviour. It can be also operated as a gold strike electrolyte.

The deposits are solderable, low in pores, ultra-bright, hard and abrasion-resistant. They have a constantly low contact resistance. Therefore the electrolyte is excellently suitable for the gold-plating of electronic components such as connectors, contacts and edge connectors on printed circuit boards. The optional use of the AURUNA® Inhibitor 2 offers the possibility of a reduced gold consumption of up to 15%. The inhibitor allows sharp borderlines – this reduces the size of the run-off area. Of course, the layer properties remain unaffected. The inhibitor can be removed without any residue after the plating by cleaning with activated carbon.

Electrolyte characteristics

Coating characteristics

Advantages

- Weakly acidic high-speed electrolyte

- Wide operating range

- Extremely high plating speed

- Low-pore, solderable, hard and abrasion-resistant coatings

- For electrical contacts

- Classification according to ASTM B-488-01 Type I-II, Code C-D

- The coatings are RoHS compliant

- For use in high-speed equipment

- Gold savings of up to 15% by inhibitor usage